Click on the grey tabs below to learn more…

- Introduction

- Supercharger Technology

- Intercooler Technology

- Helical Gearset Upgrade

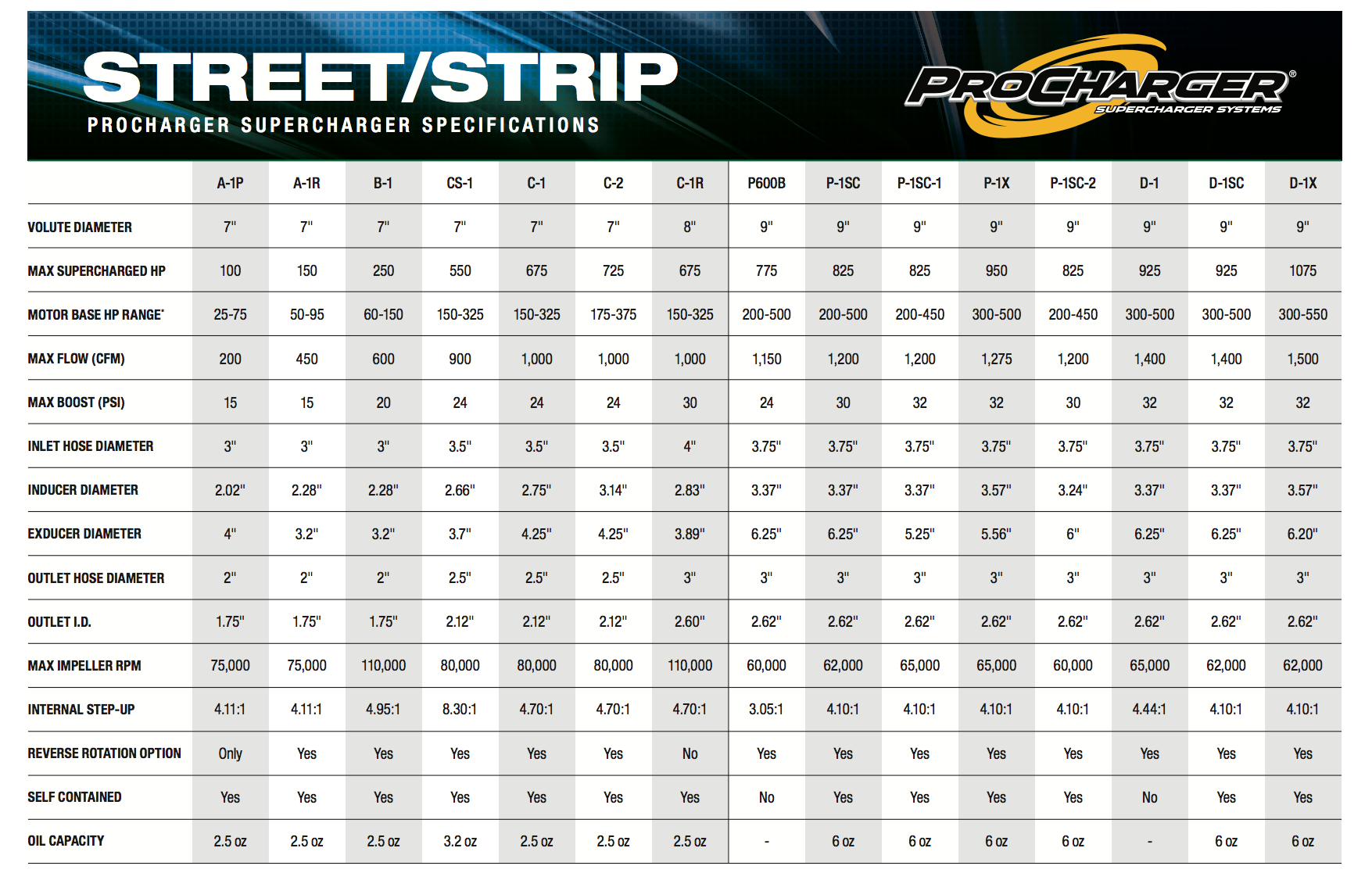

- Street Unit Specs

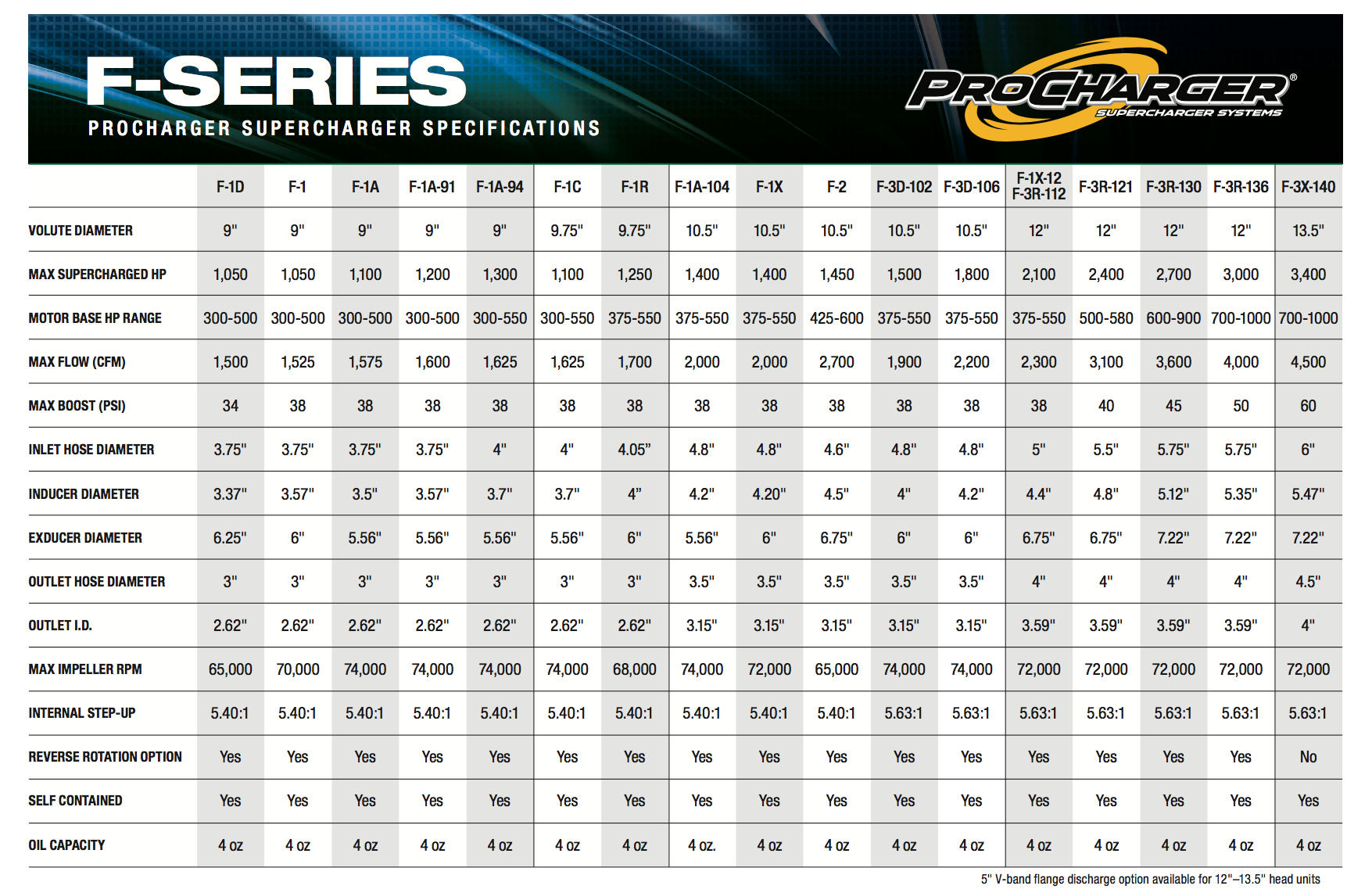

- Race Unit Specs

- Race Superchargers

- Bypass Valves

- Intercooler Options

- P1X/D1X Upgrade

Introduction to Procharger Superchargers

ProCharger supercharger kits are absolutely the most powerful and reliable supercharger systems available for your vehicle. For street use or at the track, Intercooled ProCharger supercharger systems will deliver the largest increase in horsepower and torque available from any supercharger system. And thanks to the extremely low charge air temperatures provided by ProCharger technology, ProCharger kits also provide much better engine longevity by protecting your motor from detonation. ProCharger systems are designed with a fundamental understanding of the physics behind supercharging, and are engineered to the highest quality standards.

It is this approach that allows ATI to offer exclusive features which improve both the performance and reliability of ProCharger systems relative to other products. For example, it is simply an undisputed fact that lowering charge air temperatures will substantially improve both performance and engine longevity, and ATI provides the coolest intake charge air temperatures in the industry by a wide margin. Similarly, by using CNC machining and nearly indestructable 7075 T-6 aircraft aluminum to produce the largest and strongest impellers in the industry, ATI is able to again improve both performance and reliability. ProChargers are the only centrifugal superchargers to incorporate billet impellers in production models, and this is another example of ATI’s technical leadership. This quality and durability in turn allows customers to have further peace of mind knowing that ProCharger superchargers are also backed by the best warranty in the industry, for the highest boost and power levels. For more information on the physics behind supercharging and the advantages of ProCharger technology, see the ProCharger Technology page.

In addition to absolutely unmatched performance and reliability, ProCharger supercharger kits also offer the following benefits to customers:

QUALITY

ProCharger supercharger kits are produced from the finest materials available. All castings are poured from “virgin” 356 aluminum alloy and heat-treated to a T-6 hardness before CNC machining. ATI’s exclusive billet impellers are machined from 7075 T-6 aircraft aluminum, while the super precision bearings used in all ProCharger models are made in the USA, and are of a consistently higher quality and speed/load rating than those used by any of our competitors. In fact, ProCharger superchargers are so reliable that they are used as standard equipment by many leading boat manufacturers in the extremely demanding marine environment.

COMPLETE SYSTEMS

Fuel-injected automotive and truck ProCharger Systems are generally 100% complete, with all the components needed for an attractive, OEM-quality installation. An exception is larger fuel injectors, as some systems exclude these, especially if larger fuel injectors are only needed for upgraded boost and power levels. All hardware is of the highest quality, and fuel-injected systems include a high-flow external fuel pump as standard equipment if necessary for proper fuel delivery. Carbureted systems are complete with the exception of the carburetor and fuel system, which depend upon an individual’s specific motor and performance needs.

WARRANTY

ProCharger superchargers are absolutely the most reliable (have the lowest failure rate) in the industry, and are backed by the industry’s best warranty coverage. It is not uncommon to find ProCharger kits warrantied for 1 year at power levels which our competitors will not even warranty for 1 day.

EMISSIONS

Many ProCharger Complete Intercooled Supercharger Systems meet both EPA and CARB emissions requirements. To verify the ProCharger offering for your specific application has emissions approval please contact your ProCharger Dealer or you can also verify EO numbers at http://www.arb.ca.gov/msprog/aftermkt/devices/amquery.php

SUPERCHARGER QUALITY FROM THE INNOVATOR AND LEADER

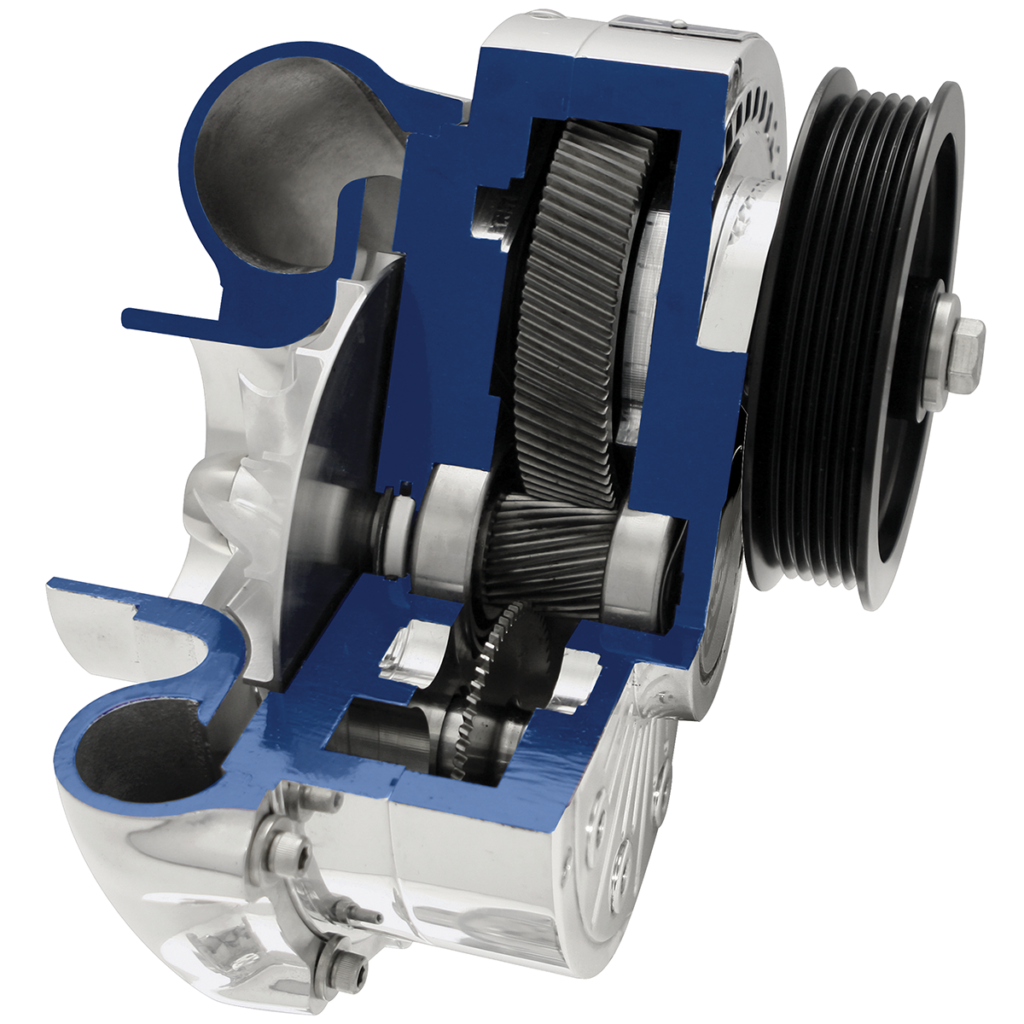

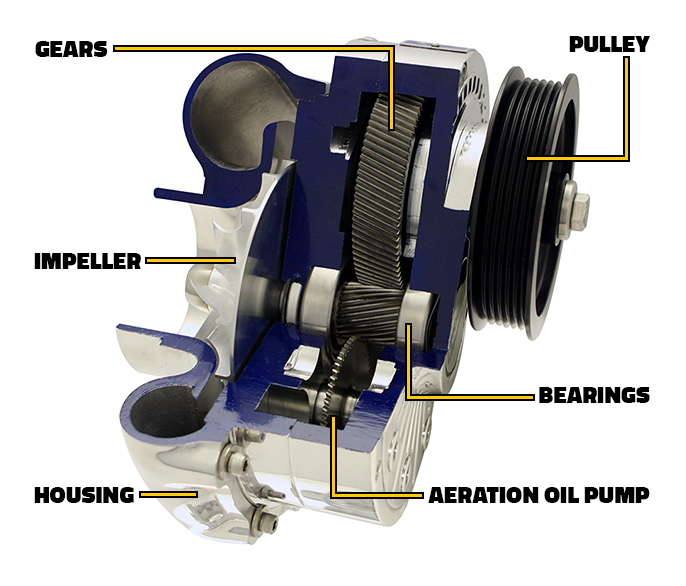

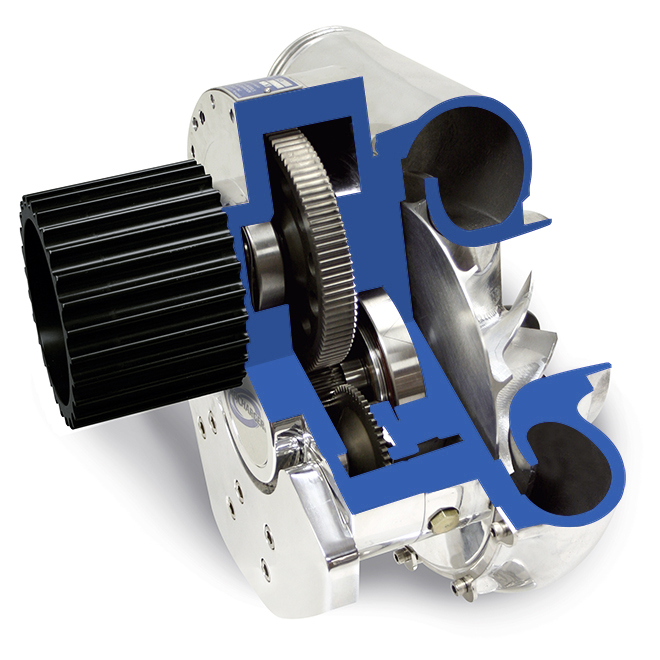

ATI’s self-contained (SC) ProCharger models are the first and only gear-driven centrifugal superchargers to feature self-lubrication, and contain the industry’s most advanced technology. In addition to the patented self-contained oiling design, SC ProChargers also feature the highest step-up ratio, exclusive billet impellers, and the industry’s only billet gearcases for superior rigidity, sealing and appearance. These proven self-contained ProChargers were designed specifically for internal lubrication and have become the industry standard.

The best-selling P-1SC-1 shares many of the design elements which deliver the record-setting durability and performance of ProCharger competition superchargers, and is also quiet and street legal. With their rugged design, these ProChargers are the only self-contained superchargers durable enough to be backed with a 3 year warranty and powerful enough to harness the benefits of intercooling.

The patented SC design eliminates the need for oil lines and punching a hole in the oil pan, thanks to an exclusive oil pump. This pump aerates the oil to create the oil mist lubrication required for the ProCharger’s precision bearings and gears. This oil pump (aeration pump) does not require priming at start-up, and oil changes are required only every 6,000 miles. Additionally, instead of being forced to utilize engine oil or the grease in sealed bearings, SC ProChargers are lubricated with an extremely high quality synthetic oil which is specifically engineered for high speed use, and produces the least frictional heat and parasitic load. The self-contained design also eliminates the heat that is transferred to a supercharger by engine oil in oil-fed applications, and avoids the risk of clogged supercharger oil lines, oil drainage problems, or engine oil leakage.

By combining advanced supercharger transmission design with the highest quality oil, SC ProChargers produce a larger net power gain because they run cooler and consume less power than comparable oil-fed designs. SC ProChargers also feature an internal step-up ratio of 4.10:1 for improved belt tracking and traction, and maximum low-rpm boost and power.

ProCharger is also the first and only manufacturer to offer the choice of standard or helical gearset for noise reduction on the P-1SC-1 and the D-1SC supercharger models.

AIR-TO-AIR ADVANTAGE

It’s a simple fact of physics: cooler air makes more power. On street driven vehicles, air-to-air intercooling is a natural fit because it locates the intercooler at the front of the vehicle where it is exposed to a constant supply of cooling airflow. Experts agree that air-to-air inherently provides better cooling and reliability than air-to-water intercoolers for street use. Engineered with large-volume air plenums, ProCharger’s air-to-air intercoolers utilize a highly effective and extremely durable bar and plate intercooler core design that provides large surface areas for superior levels of heat dispersion.

Air-to-air intercooling is a highly effective one step process and represents a fundamental ProCharger advantage. Compressed air enters one side of the intercooler, making its way into the bar and plate core. Once in the core, the compressed air is cooled by the airflow moving through the passages or fins of the intercooler. Next, this cooler, denser air is routed into the throttle body and into the engine. ProCharger intercoolers typically feature best in class effectiveness of 70-80%.

On the other hand, air-to-water intercooler systems use a complex arrangement of intercooler cores, hoses, fittings, a coolant pump, electrical connections and yes, a secondary air-to-air heat exchanger. In street applications, an air-to-water intercooler is in fact an air-to-water-to-air system.

With air-to-water-to-air, heat is first removed from the air by the water circulating through the intercooler. This heated water is then pumped through a radiator, and returned to a tank. The overall system performance is “watered down” because its effectiveness is a diminishing function of the individual effectiveness of each heat exchanger. For example, 65% intercooler effectiveness and 60% radiator effectiveness produce a combined effectiveness of only 49%. “Two step” cooling is, by design, inherently less effective. Typically exposed to heat soak from the engine, air-to-water-to-air intercoolers are complex, difficult to install, and less reliable than air-to-air intercooling.

HELICAL GEARS = QUIETER PERFORMANCE

For those wanting to have less noise when driving, our helical gearset makes a lot of sense. These gears are machined of high quality, hardened steel ensuring many miles of reliable, smooth performance. Helical gearsets are ideal for those Durangos with a stock or OEM exhaust.

HELICAL SUPERCHARGER GEARSET OPTION FOR NOISE REDUCTION

Since introducing the industry’s first self-contained, gear driven supercharger back in 2000, ProCharger’s design has proven itself over millions of miles and countless passes down the drag strip. With it’s billet aluminum transmission case, industry leading step-up ratio, high-efficiency compressor and aerospace billet impeller designs, ProCharger’s lineup of high-efficiency superchargers have become the standard by which others are measured.

Now, ProCharger is extending our lead even further with the introduction of a helical gearset for a significant reduction in supercharger sound levels. This new helical gearset, along with a few other internal design modifications, results in a supercharger with all the same power potential as the standard blower, but at reduced sound levels, especially at engine idle speeds. With this new offering ProCharger becomes the first and only supercharger manufacturer to offer customers a choice of gearset design and noise level, as the standard design continues to be available.

We know that many ProCharger owners want the world to know, and hear, their new-found ProCharger horsepower. However, for those owners who want a more stealthy horsepower profile, the new helical gearset option provides that choice. Additionally, not only is ProCharger the only supercharger manufacturer to offer customers their choice of sound levels, ProCharger is the only centrifugal manufacturer to offer noise reduction on it’s “upgraded”, highest flowing street/strip model.

The new helical gearset is available on ProCharger P-1SC, P-1SC-1 and D-1SC supercharger models and must be specified at the original time of order.

100 CHAMPIONSHIPS IN 15 YEARS

No competitor offers more winning choices than ProCharger. And ProCharger racers have won over 100 national championships in the past 15 years, something we are certainly proud of here at ProCharger. Built on years of racing success and R&D knowledge, the ProCharger line of superchargers produces the most power and increases your chances of winning.

No external lines or external pumps required – Our superchargers are the easiest to install, operate, and maintain. Our superchargers have an efficient internal oil / self-contained design so no hassles when it comes to racing.

Staging your car is a breeze with ProCharger! Compared to turbos, no violent staging or bumping your car is required. Just roll in, set your trans brake, rev it up and turn a great light! And compared to nitrous, no more flirting with disaster. Just predictable, consistent performance round-after-round with a ProCharger supercharger.

ProCharger CrankDrive geardrive is completely compatible with ProCharger F3 series race superchargers. Simplify installation with the only gear drive designed and manufactured by a supercharger manufacturer, the award winning CrankDrive. We also offer cog belt setups for anything from high HP street/strip combos to Top Dragsters making over 2000 HP. We got you covered for most any drag racing setup.

ProCharger superchargers are made from the strongest materials – High strength, aircraft grade billet aluminum is what makes our superchargers hold up pass-after-pass, letting you concentrate on getting the most out of your race engine/chassis combo.

ProCharger superchargers are also backed by the industry’s best service and support. Check out our supercharger specs sheet below and racing applications table for recommended superchargers of each racing class. Any questions, just give us a call. We have real people right here in the USA to take your call. Join the ProCharger winning team and head to the winner’s circle!

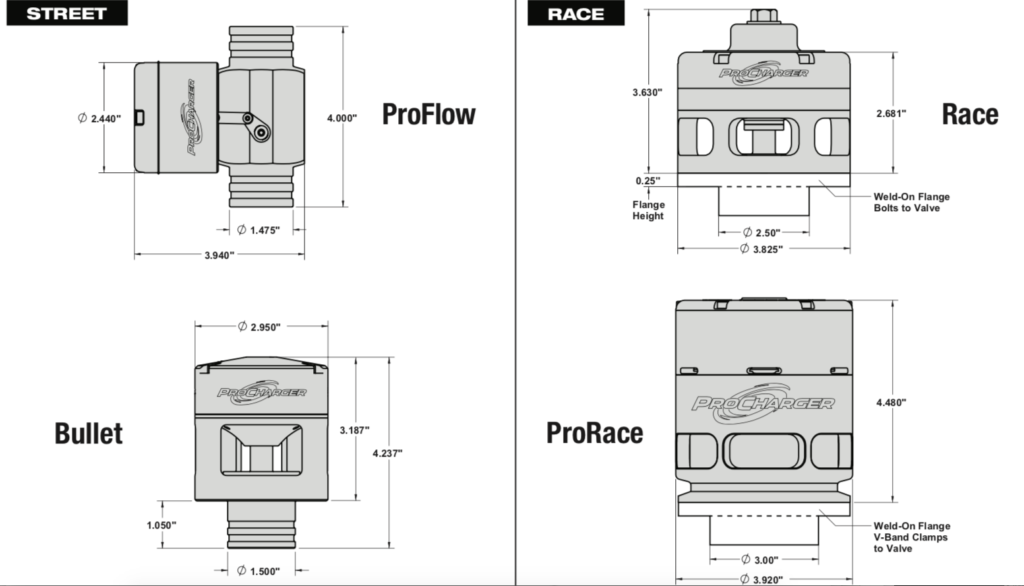

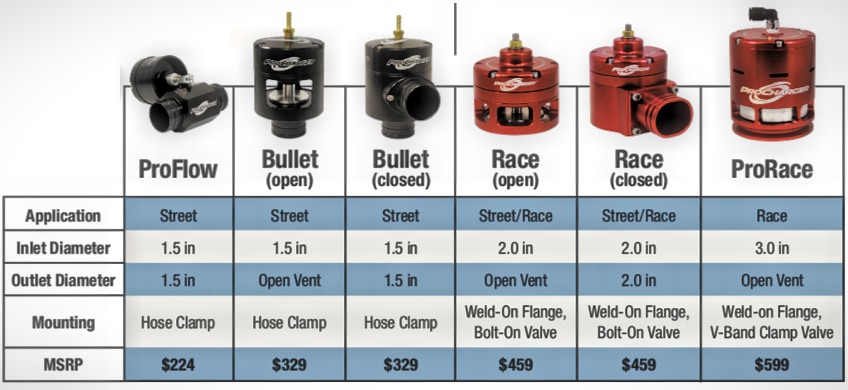

BYPASS VALVES – SURGE VALVES FOR STREET AND RACE APPLICATIONS

WHY ARE BYPASS VALVES IMPORTANT?

For supercharging applications, surge occurs when excessive boost or pressure spikes as a result of a sudden throttle blade closing, which can cause severe damage to a supercharger and is why we mandate all ProCharger supercharger installations use a bypass valve.

A SIMPLE WAY TO LOOK AT OUR OFFERINGS IS BASED ON YOUR ENGINE’S HORSEPOWER OUTPUT LEVEL:

700 HP OR LESS – PROFLOW OR BULLET BYPASS VALVE IS RECOMMENDED, DEPENDING ON PREFERENCE

ProFlow Valve: The ProFlow valve is the standard surge valve option for our street supercharger systems and kits. Compact in size. It can be fitted into tight spots when space is limited. Its butterfly valve is extremely durable and reliable, and this design creates a straight airflow path which achieves excellent flow for its size. The ProFlow valve can also be paired with a small air filter to minimize noise.

Bullet Valve: This surge valve’s compact design also makes it fit easily in tight spaces. It comes in both an open and closed format. The closed format allows you to recirculate air back into the system, or instead to run to an air filter to minimize noise.

701-1200 HP – RACE OPEN BYPASS VALVE IS RECOMMENDED

Race Valve: This is the industry leading surge valve for both street and race applications. The larger valve diameter is designed for high flow applications.

1201-3500 HP – PRORACE BYPASS VALVE IS RECOMMENDED

ProRace Valve: One ProRace Valve outflows any other single valve on the market and is our highest-hp bypass valve option. This massive flow capacity comes from a piston style valve design (patent pending) that allows for a significant increase in curtain area over traditional style valves, while still fitting into a reasonably sized package. It also incorporates a v-band clamp for an easy install.

OPEN VS. CLOSED BYPASS VALVES

Open – Vents to atmosphere and creates a distinctive “whoosh,” when the throttle blade suddenly closes, which a lot of people enjoy the sound.

Closed – Vents to an external air filter or an internal tube for rerouting excess boost pressure back upstream of supercharger for a more quiet and subtle sound. More ideal for street applications where someone wants more of a silent or stealth operation of the supercharger.

For street applications, our complete systems and tuner kits come with the proper bypass valve based on the vehicle’s horsepower output level so, no need to worry about the right one. However, we do offer upgrade options for our Systems and Tuner Kits with our Race bypass valve family for those seeking a little more sound or those that like the cool look of the anodized finish of our Race bypass valves.

BYPASS VALVES ARE NOT WASTE GATE RELIEF VALVES

Contrary to most perceptions a bypass valve is designed to relieve boost/pressure when the throttle blade is closed. Conditions such as idle, during shifts, and backing off throttle during tire slip conditions are very important to have a bypass valve. A bypass valve utilizes a vacuum line port behind the throttle blade and vents when detecting an immediate change in pressure. Bypass valves are different from a wastegate relief valve, which operates as a pressure relief valve and opens or vents excess pressure when a certain pressure is achieved.

WOULD YOU EVER WANT TO INSTALL A WASTE GATE RELIEF VALVE WITH A PROCHARGER SUPERCHARGER?

The correct answer is no. Our superchargers are designed to provide maximum boost and efficiency at the maximum engine rpm and by adding a wastegate relief valve to vent that boost is defeating the whole purpose of having an efficient ProCharger supercharger. Proper supercharger pulley size and knowing how much boost your engine can handle at its rated max rpm are the keys to success with a proper ProCharger setup.

PROCHARGER INTERCOOLERS: HIGH PERFORMANCE THROUGH INNOVATION

It’s true, intercoolers play a huge roll in creating high HP while also maintaining engine reliability in a supercharger system. However, this important part is often never mentioned when comparing supercharger systems. In this blog we will cover the items that set the ProCharger intercoolers apart from the rest, to help illustrate what gives our supercharger systems the coolest air charge temperatures, and thus the largest, most reliable power gains available.

Design

For starters, ProCharger uses the highly effective (and durable) “Bar and Plate” design for street/strip intercooler cores-the core itself is not only engineered to be of the proper size for the application, but also the core “spacing” of the bars and plates to ensure proper airflow flow to fluid systems behind the intercooler (IE: Radiator/Condenser).

One of the often overlooked aspects of an intercooler is weight. We all know that if its lighter, its faster, so with that in mind ProCharger engineers design light weight stamped sheet metal aluminum end tanks for our intercoolers, instead of commonly used (heavy) cast aluminum air-to-air units – not to mention the weight of a pump, secondary heat exchanger, coolant reservoir and coolant of an air-to-water-to-air intercooler system.

ProCharger not only tests to ensure the pressure drop across the core’s flow path is at its absolute lowest, but also checks for proper temperature reduction between inlet and outlet. When intercoolers are being tested for their effectiveness, we are looking for the coolest air charge possible, but we also want to make sure the supercharger isn’t working to hard to “push” air through the core itself.

_

Sizing and Options

Another important aspect that sets ProCharger apart is that for most of our systems, we offer multiple intercooler sizes (or arrangements) to best fit your HP goals or driving habits.

For the 2011+ 5.0L Mustang, the animation below illustrates (3) different intercooler options in the form of the HO intercooler system, Stage 2, and Race. The HO intercooler features a highly efficient crossflow intercooler core for stock or slightly modified applications. Our Stage 2 offering swaps to a large side to side flow core that is 3.5″ thick offering great flow for modified applications pushing the power levels. For those going for the ultimate in charge cooling, the Race Intercooler with 4.5″ thick core can be ordered that features a MASSIVE 1296 cubic/inch Cooling Core!

HO Intercooler = 540 cubic/in Cooling Core

Stage 2 Intercooler = 1008 cubic/in Cooling Core

Race Intercooler = 1296 cubic/in Cooling Core

The C7 Stingray Corvette is a car that is just at home on the road course as it is at the drag strip. At ProCharger we knew having an intercooler layout for each was needed. So using the same massive 972 cubic inch cooling cores, we developed both horizontal and vertical layouts, to match different driving habits. We recommend the vertical style unit for drag racing applications where high hp and absolute maximum cooling of the air charge is needed in short bursts. The horizontal unit is better-suited for road racing applications, where long periods of wide-open-throttle demand maximum airflow to other factory cooling systems.

Vertical Intercooler = 972 cubic/in Cooling Core

Horizontal Intercooler = 972 cubic/in Cooling Core

The next animation shows the two intercooler options available for the 2011+ 6.4L SRT Challenger. The HO intercooler features a high flow, top-to-bottom core design that maximizes available airflow through the cars front fascia. However, for those pushing horsepower/boost levels, and wanting the largest air-to-air intercooler available for new HEMI-powered cars, the Race Intercooler option with its 970 cubic inch core is also available.

_

–

–

Stage 2 Intercooler = 423 cubic/in Cooling Core

Race Intercooler = 970 cubic/in Cooling Core

One of the most modified platforms we sell superchargers for is the new Gen 5 Camaro SS. To ensure we have the perfect intercooler for its wide range of power levels, ProCharger is happy to offer (2) different intercoolers. Much like as the 2011+ Mustang 5.0L, the base HO system offers a high-flowing vertical core design for stock or mildly modified vehicles. For those pushing the power levels with modified motors or using their Camaro SS for heads-up racing, we offer the Race unit that switches to a side-to-side core and 4.5″ thick core, for the ultimate in charge temp cooling.

_

HO Intercooler = 486 cubic/in Cooling Core

Race Intercooler = 1296 cubic/in Cooling Core

RAISING PERFORMANCE AND TECHNOLOGY TO THE “X” LEVEL…

Obviously, if you already have a ProCharger “P” or “D” and are looking for exciting results, we have good news! Existing head units can easily be converted to the “X” design. The bang for the buck is as good as the power gains. Naturally many new system orders can be optioned to include both the P-1X and D-1X head units.

P-1X/D-1X BULLET POINTS:

- More power per psi, more maximum HP, and cooler charge air temperatures

- P-1X™ is 875+ HP capable and is a direct bolt-in upgrade for the P-1SC-1

- D-1X™ is 1000+ HP capable and is a direct bolt-in upgrade for the D-1SC

- Designed for today’s high flowing modern V8 engines producing 400+ naturally aspirated HP

- Available now as optional upgrade with ProCharger Systems and Tuner Kits

- Highly durable, High HP designs with a compact new state-of-the-art 9.0″ housing/volute

- Higher efficiency produces cooler charger air temperatures and reduces parasitic engine load

- Uses same proven gearcase as P-1SC-1 and D-1SC–also available with standard or reduced noise level

- P-1X/D-1X volutes are slightly larger than P-1SC-1/D-1SC volutes

For those that enjoy some visual side by side shots, here you go.

D-1SC (left) D-1X (right)

Starting with the impeller you will notice that the “X” impeller is a bit taller and a more swept blade design.

Internally the volute pocket has also been changed, as well as a single rib on the discharge outlet.

Externally the volute is drastically different, however still features a compact 9.0″ diameter footprint.